PRODUCT

- 홈

- Product

- Carbon & Grasphite

Carbon & Grasphite

Carbon & Graphite?

As the modern industry develops, Carbon and Graphite are being applied as the core components in various industrial fields.

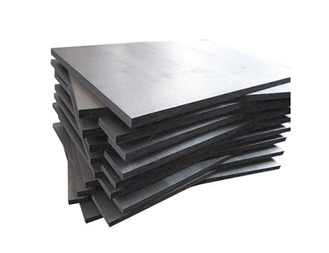

Carbon and Graphite are made through press molding and heat-treatment at high temperature by mixing cokes and pitch binder gained in petroleum refining process. Carbon is made through heat treatment for tens of days in a sintering furnace at temperature 1000~1300 ˚C. Through the graphitization process, The Amorphous carbon is reprocessed with heat treatment at 2500~ 3000 ˚C in an electric resistance furnace to obtain graphite having a crystalline structure. The Carbon and Graphite are classified into Extruded graphite and Isotropic graphite depending on molding method before firing, and are classified and used as per its mechanical properties and uses.

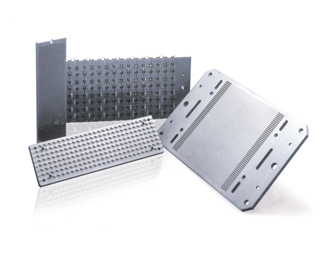

Isotropic graphite has a fine particle structure compared to Extruded graphite and is a high-density / high-strength product. At the same time, it has superior properties compared to Extruded graphite in most properties. Typical applications of graphite are parts for semiconductor production, parts for vacuum heat treatment (heater, etc.), dies for casting, and electrodes for electric discharge processing (EDM).

Features of Graphite

- 1 Excellent heat resistance

- 2 Low specific gravity compared to metal

- 3 Increased strength at high temperature

- 4 Low thermal expansion

- 5 Excellent thermal conductivity

- 6 Excellent electrical conductivity

- 7 Self-lubricating

Use of Graphite by industry

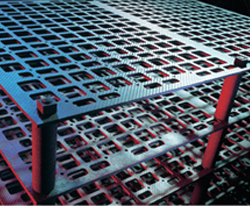

1) Sintering

In the sintering process for powder metallurgy products, graphite is used as a tray and box that transports the sintered body when the products are put into the continuous furnace and heat treatment furnace. In addition, during the manufacturing process of industrial diamond tools, graphite is used as a mold for pressure sintering of powdered raw materials. Isotropic Graphite, which has excellent mechanical properties and strong heat resistance, is an essential element in producing sintered products.

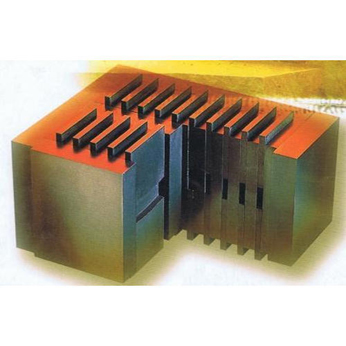

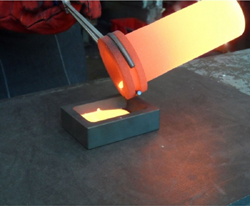

2) Continuous casting

Graphite die (nozzle) is used as a core material for producing copper and copper alloy products. It is used in the production of nonferrous metals such as wire, tube and slab, and isotropic graphite is suitable for continuous casting. In addition, high thermal conductivity and non-adhesion with molten metals are characteristic of graphite products.

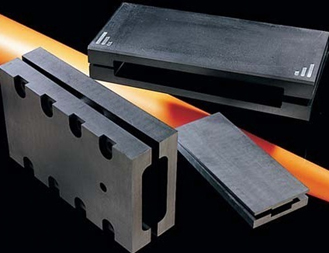

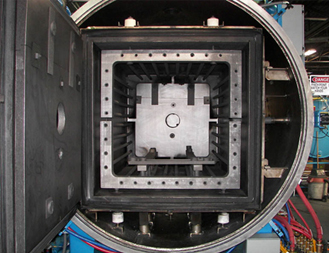

3) Industrial heat treatment Furnace

As a core component of an industrial vacuum furnace, a number of components including the heater, heater connector, and electrode, which are heating elements inside the furnace, are made of graphite. The heater using the specific resistance of graphite can be stably used even at ultra-high temperatures of 2000 ˚C or higher, and graphite felt, an insulating material, is used as an internal component of other heat treatment furnaces.

In addition to these representative core parts, it can be used in various application products such as crucibles, hot press molds, stirring rods (impellers), and brazing jigs.

4) Mechanical carbon

It can be applied to mechanical sealing and bearing products by utilizing the characteristics of carbon's self-lubricating activity and chemical resistance. It is necessary to select materials such as carbon graphite, resin/metal impregnation, and SiC depending on the usage conditions and environment. As an application field, it is applied to rotary motion parts such as common pumps, chemical pumps, compressors, and submersible pumps.

Ex) Joint seal, radial bearing, thrust bearing, mechanical seal ring....

5) Other carbon application materials

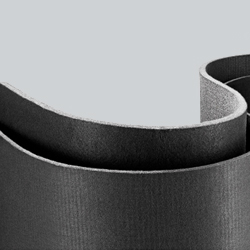

C/C Composite (carbon fiber reinforced carbon composite material)

Compared to isotropic / extruded graphite, it is light and easy to handle with low density. On the other hand, it has excellent strength and does not break.

Ex) Heater, bolt, sinter tray, etc...

Felt (Insulation material) Graphite Felt is used as an insulating material for heat shielding inside and outside of the Hot-Zone, and it can be used by selecting among Rigid Felt and Soft Felt according to the Hot-Zone type and operation method.

TYPICAL PROPERTIES OF GRAPHITE MATERIALS

| Grade | Bulk Density | Flexural Strength | Tensile Strength | Compressive Strength | Electrical Resistivity | Thermal Conductivity | Coefficient of thermal | Elastic modulus | Hard ness | Porosity rate | Particle Size |

|---|---|---|---|---|---|---|---|---|---|---|---|

| expansion | |||||||||||

| g/cm3 | MPa | MPa | MPa | μΩm | W/(m・k) | X10-6/K | HPa | HSD | % | μm | |

| ET-10 | 1.75 | 58.8 | 34.3 | 98 | 14 | 104.4 | 3.8 | 10.8 | 50 | 15 | 5 |

| ET-11 | 1.77 | 72 | 50.4 | 130 | 17 | 70 | 4.2 | 10 | 59 | 14 | 13 |

| ET-15 | 1.84 | 65 | 45 | 111.4 | 10.5 | 120 | 4.5 | 11 | 52 | 11 | 15 |

| ET-21 | 1.86 | 68 | 48 | 120 | 2 | 110 | 4 | 12.5 | 56 | 11 | 15 |

| ET-34 | 1.86 | 70 | 50 | 120 | 9 | 150 | 3.9 | 11 | 54 | 11 | 5 |

| T-2 | 1.72 | 47 | 24.5 | 68.6 | 14.4 | 104.4 | 4.5 | 9.8 | 53 | 16 | 10 |

| T-4 | 1.78 | 49 | 29.4 | 88.2 | 12 | 81.2 | 4.7 | 10.3 | 55 | 15 | 10 |

| T-5 | 1.8 | 58.8 | 33.3 | 107.8 | 14 | 75.4 | 4.9 | 11.4 | 65 | 14 | 10 |

| T-6 | 1.9 | 98 | 49 | 171.5 | 16 | 58 | 6.2 | 14.7 | 75 | 9 | 1 |

| T-8 | 1.85 | 88.2 | 46 | 156.8 | 15 | 81.2 | 6.5 | 13.7 | 75 | 9 | 5 |

| TX-76 | 1.87 | 81 | 52 | 159 | 19.5 | 60 | 5.9 | 14.1 | 77 | 10 | 6 |

| EX-50 | 1.75 | 63.7 | 36.3 | 98 | 12.5 | 92.8 | 4 | 10.8 | 55 | 15 | 15 |

| EX-60 | 1.8 | 80 | 56 | 140.2 | 13 | 110 | 5 | 12.1 | 62 | 14 | 10 |

| EX-70 | 1.85 | 68.6 | 49 | 137.2 | 15 | 81.2 | 6 | 13.7 | 70 | 10 | 6 |

| EX-75 | 1.8 | 80 | 55 | 150 | 16 | 80 | 4.7 | 11.1 | 68 | 14 | 5 |

| ED-4 | 1.9 | 98 | 49 | 176.4 | 17 | 58 | 6.5 | 14.7 | 85 | 9 | 1 |

| EDX-7 | 1.82 | 95 | 55 | 125 | 17 | 105 | 6.6 | 13.3 | 68 | 12 | 3 |

| 2191 | 1.75 | 44 | 97 | 10.9 | 116 | 4.2 | 80 | 12 | 15 | ||

| 2020 | 1.77 | 45 | 99 | 15.5 | 85 | 4.3 | 95 | 9 | 15 | ||

| 2124 | 1.84 | 58 | 124 | 11.4 | 112 | 5.5 | 80 | 8 | 13 | ||

| 2715 | 1.82 | 55 | 121 | 23 | 56 | 6.5 | 100 | 10 | 13 | ||

| 2720 | 1.8 | 53 | 117 | 21.6 | 60 | 5.0 | 85 | 10 | 13 | ||

| 2333 | 1.86 | 76 | 167 | 16 | 81 | 6.0 | 95 | 6 | 5 | ||

| G347 | 1.85 | 49 | 31.4 | 11 | 116 | 5.5 | 58 | 12 | 11 | ||

| FE250 | 1.75 | 24.5 | 8 | 174 | 3.3 | 35 | 17-20 | 0.8(mm) |